Cold Bugging Out

Sadly for these overclockers, achieving significantly sub zero temperatures isn’t just as easy as filling the pots with LN2 and waiting for the CPU to reach -190°C before clocking the nuts off of it. Just as a processor can overheat, they can also become too cold, a process known in the game as “Cold Bug.” The problem is that due to very tiny inconsistencies in the processor manufacturing process, where the Cold Bug can strike at different temperatures despite the exact same model of CPU being used.Throughout the two days of the event, we saw QX9770 processors cold bugging at as high as -70°C, all the way down to -160°C, so there’s a real pot luck aspect of the event; if a team gets handed a badly cold bugged processor, they’re at an automatic disadvantage.

As well as the problem of cold bug, processors are also susceptible to cold boot issues, where the processor, just like a car engine, is just too cold to start up. Once booted, the processor can be pushed to much lower temperatures, but due to the frequent restarts required for BIOS voltage tweaks, teams have to be careful not to push their luck with the cold boot and cold bug temperatures.

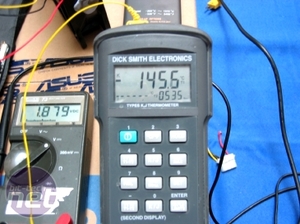

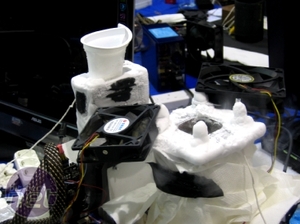

Click to enlarge - Temperature read outs are a must, although some teams didn't seem to mind the ice!

If a processor does cold bug, or cold boot, then it’s time to break out the hairdryer (or in the case Team GB, an industrial paint stripper – the right tool for the right job as the saying goes) and point it down the throat of the cooling pot, to knock the CPU temperature back up to a level where it’ll boot back up – hence the need for condensation proofing of components!

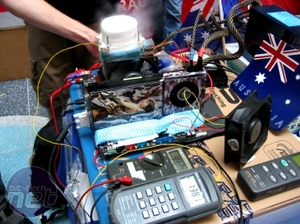

The constant threats of cold boot and cold bug mean that overclocking teams are almost always in twos; a driver and a pourer. The driver is the guy who’s tinkering with the BIOS, altering speeds and voltages and generally operating the PC to achieve the best overclock possible.

The pourer does exactly what the term implies, pouring the LN2 into the pots and managing the temperatures of the gear, trying to avoid the twin threats of cold bug and cold boot. Both positions require a fair amount of experience and expertise to achieve the maximum result, and the process can become pretty stressful when the LN2 starts to run low in the middle of a benchmark.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.